Katool KT-T835 Wheel Clamp Tire Changer Machine

Couldn't load pickup availability

Shipping-FAQ's

Shipping Info

At Mechanic Superstore, our commitment is to provide you with the best customer service possible. For this reason, we offer you all kinds of delivery options so that you can choose the one that suits you best.

I Have The Equipment To Unload My Order

- Do you have a forklift, a high-capacity hoist, or a tractor in your facility? In that case, this option may be the one for you.Aspects to keep in mind when choosing this option.

- The most popular 2-post lifts (with 9,000 lb and 10,000 lb capacity) have a shipping weight of approximately 1,400 lbs and 1,900 lbs, respectively. On the other hand, a 15,000 lb capacity 2-post lift has a 2,700 lb shipping weight.

- Given the packaged lift and hydraulic power unit’s weight, they cannot be unloaded from the trailer by hand. Simply put, IT IS MANDATORY TO USE A SUITABLE FORKLIFT OR HOIST FOR UNLOADING THE LIFT.

- You are solely responsible for unloading your equipment from the truck. The truck driver cannot do this for you.

- Mechanic Superstore uses trustworthy freight companies to make the deliveries. It is your responsibility to be present on the scheduled date and time of the delivery.

- There will be a receiver charge of $135 if the truck driver arrives at the designated location and the customer does not have the necessary means ready to unload the lift.

- In case you do not have the necessary equipment to unload the equipment do not worry. Mechanics Superstore offers other delivery options.

Do you have a hitch trailer to transport your lift? If so, then this might be the best option.

Aspects to keep in mind when choosing this option.

1. Mechanics Superstore and our brands’ warehouses have the means to load your car lift into an appropriate trailer.

2. Given the weight and dimensions of car lifts, we cannot load lifts directly into vehicles or trucks. To safely transport your lift, you will need a hitch trailer. Will this option not work for you? Perhaps the warehouse is too far from your location? If so, keep reading.

Think of this option as a variation of the previous one. Even so, this could be an excellent alternative to picking up the lift at one of our warehouses. Instead, we can take the car lift to a warehouse closer to your location.

You will still need a hitch trailer to transport the lift for this option, but you can save on freight costs if you have an LTL Carrier close to your shop.

Neither of the above delivery options suits you? Then we have the solution.

We will dispatch your lifts directly to a local installer in your area. This way, you will not have to worry about anything since the installer would be in charge of the logistics.

Aspects to keep in mind when choosing this option.

1. You still have to pay the freight fee to the installer (or dock hold for the installer to pick up the lift)

2. We will quote th e installation fee before you pay for the lift so that you can get an idea of the total amount to pay (car lift + freight + installation).

Do you have another delivery option in mind? In that case, do not hesitate to contact us. At Mechanic Superstore, we are open to all kinds of solutions, as long as they comply with the relevant local regulations and safety standards.

Katool KT-T835 Wheel Clamp Tire Changer Machine

The Katool KT-T835 Wheel Clamp Tire Changer Machine is engineered to provide efficient and reliable tire service for a wide range of vehicles. With its robust construction and advanced features, this tire changer is an essential tool for professional automotive workshops.

Equipped with a powerful 2.0HP motor, the KT-T835 delivers consistent performance, ensuring quick and precise tire changes. The motor's design emphasizes fast heat dissipation, contributing to its longevity and reliability in demanding environments.

The machine's dual assist arms enhance operational efficiency by providing additional support during tire mounting and demounting processes. This feature reduces manual effort and minimizes the risk of damage to the tire and rim, ensuring safe and effective service.

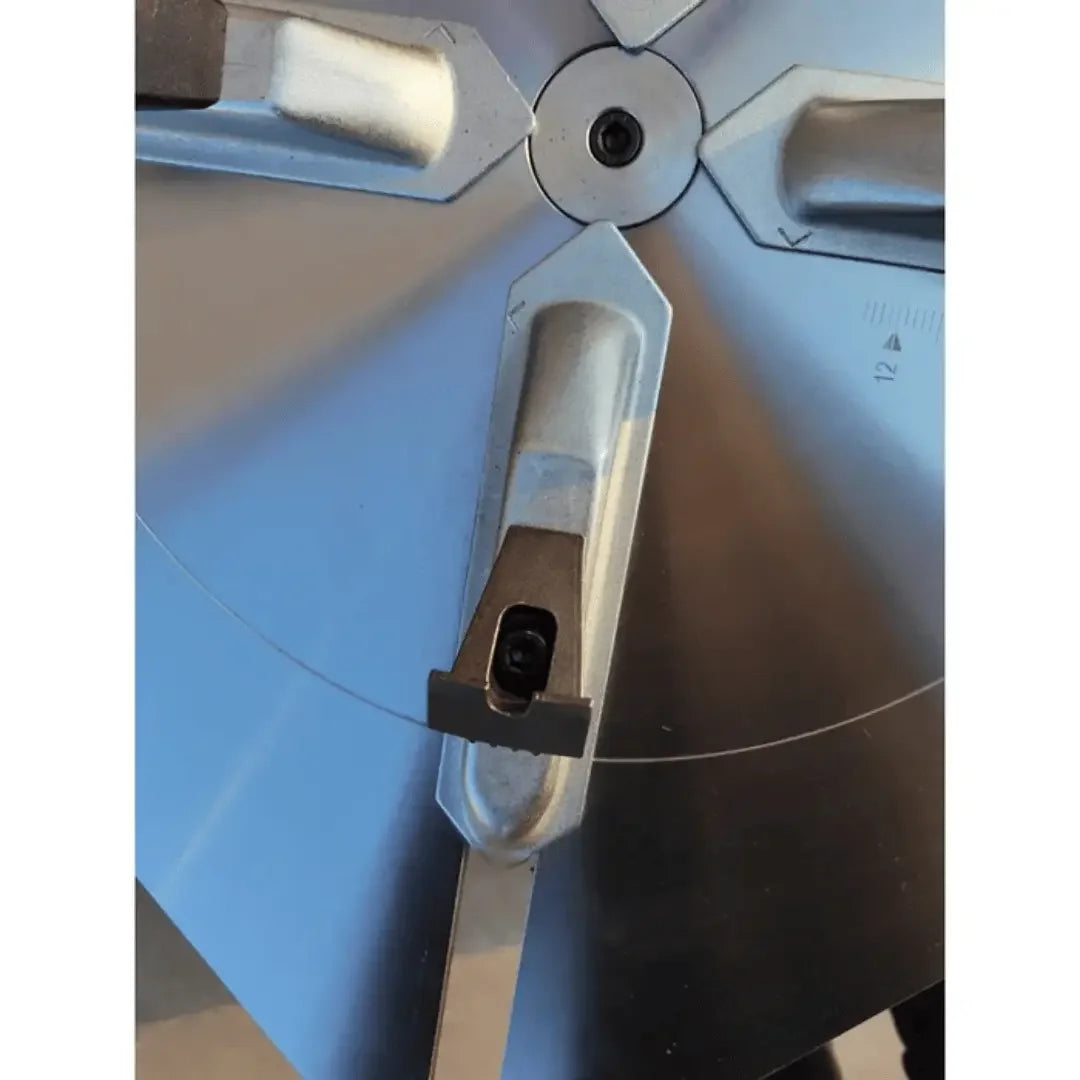

A standout feature of the KT-T835 is its bead blast seater head with a post tank. This system facilitates the rapid seating of tire beads, especially useful for low-profile tires or those with tight beads. The bead blast function ensures that the tire bead seats evenly, promoting optimal tire performance and safety.

The tire changer's clamping range is versatile, accommodating a variety of wheel sizes. It supports outside clamping from 13" to 26" and inside clamping from 14" to 28", making it suitable for a broad spectrum of tire sizes. Additionally, the machine can handle wheels with a maximum diameter of 41" and a maximum width of 15", providing flexibility for different vehicle types.

To ensure the protection of rims during service, the KT-T835 features alloy steel jaws with a deep carburization treatment of 0.8-1.1mm depth. This process enhances the jaws' toughness and hardness, while the included jaw covers safeguard the rims from potential damage.

For user convenience, the KT-T835 is equipped with an inflation gauge with pedal control. This feature allows for precise tire inflation, enhancing safety and efficiency during the tire service process.

The tire changer machine operates on a 110V 1-phase 60Hz power supply, making it compatible with standard electrical outlets in most workshops. Its air pressure requirements range from 0.8 to 1.0 MPa (116–145 psi), ensuring optimal pneumatic performance.

With a net weight of 582 lbs, the KT-T835 tire changer machine is built for stability and durability, capable of withstanding the rigors of daily use in a professional setting. Its robust construction contributes to its longevity and reliable performance over time.

Contact us for more information on tire changer machines![]()

Product Features

- Alloy steel jaw, interface carburization treatment of 0.8-1.1mm deepness, whole quenching process, making the jaw inside more tenacity and outside more hard, and take the jaw cover for protect rim

- The mounting head is made by stainless, solution treatment and interface polishing, the shape conforms to the engineering principle, with plastic cover for protect rim

- Inflation gauge with pedal control

- With high quality spade cover, effective prevent damage rim

- Pull type pedal control system, convenience for changing and maintenance

- Top level motor and pure copper winding, fast heat dissipation, low defect rate and longer using life

- With high quality filter, reliable drop oil, effective filter pressure air, and make more longer using life for pneumatic system

- For North America region used 110V/1ph/2.0HP motor ,more strong power and high efficiency working

- Double side assist arm

- Bead blast seater head with post tank

- 186mm stainless bead breaker cylinder

- Closed body for protect inside parts

Product Specifications

| Max Wheel Diameter | 41"/1040mm |

| Max Wheel Width | 15"/350mm |

| Outside Clamp | 13"-26" |

| Inside Clamp | 14"-28" |

| Power Supply | 110V 1PH/60HZ |

| Motor Power | 2.0HP/1.5KW |

| Rotation Speed | 6.1/min |

| Air Pressure | 0.8-1.0Mpa(116-145psi) |

| Net weight | 582lbs |

Tire Changer Installation – Quick Guide

- Prepare Area: Use a level concrete floor with space and proper power/air access.

- Unpack & Inspect: Check for damage or missing parts.

- Anchor Machine: Bolt to the floor if required.

- Connect Power: Match voltage, follow wiring diagram, and ground properly.

- Attach Air Supply: Connect to regulated compressed air (110–145 PSI).

- Function Check: Test all controls – turntable, bead breaker, inflation.

- Calibrate & Lube: Add tire lube, adjust settings, and ensure safe operation.

Pick Up and Delivery

Call, text, or chat with us if you have questions. 866-774-7743