Shipping-FAQ's

Shipping Info

At Mechanic Superstore, our commitment is to provide you with the best customer service possible. For this reason, we offer you all kinds of delivery options so that you can choose the one that suits you best.

I Have The Equipment To Unload My Order

- Do you have a forklift, a high-capacity hoist, or a tractor in your facility? In that case, this option may be the one for you.Aspects to keep in mind when choosing this option.

- The most popular 2-post lifts (with 9,000 lb and 10,000 lb capacity) have a shipping weight of approximately 1,400 lbs and 1,900 lbs, respectively. On the other hand, a 15,000 lb capacity 2-post lift has a 2,700 lb shipping weight.

- Given the packaged lift and hydraulic power unit’s weight, they cannot be unloaded from the trailer by hand. Simply put, IT IS MANDATORY TO USE A SUITABLE FORKLIFT OR HOIST FOR UNLOADING THE LIFT.

- You are solely responsible for unloading your equipment from the truck. The truck driver cannot do this for you.

- Mechanic Superstore uses trustworthy freight companies to make the deliveries. It is your responsibility to be present on the scheduled date and time of the delivery.

- There will be a receiver charge of $135 if the truck driver arrives at the designated location and the customer does not have the necessary means ready to unload the lift.

- In case you do not have the necessary equipment to unload the equipment do not worry. Mechanics Superstore offers other delivery options.

Do you have a hitch trailer to transport your lift? If so, then this might be the best option.

Aspects to keep in mind when choosing this option.

1. Mechanics Superstore and our brands’ warehouses have the means to load your car lift into an appropriate trailer.

2. Given the weight and dimensions of car lifts, we cannot load lifts directly into vehicles or trucks. To safely transport your lift, you will need a hitch trailer. Will this option not work for you? Perhaps the warehouse is too far from your location? If so, keep reading.

Think of this option as a variation of the previous one. Even so, this could be an excellent alternative to picking up the lift at one of our warehouses. Instead, we can take the car lift to a warehouse closer to your location.

You will still need a hitch trailer to transport the lift for this option, but you can save on freight costs if you have an LTL Carrier close to your shop.

Neither of the above delivery options suits you? Then we have the solution.

We will dispatch your lifts directly to a local installer in your area. This way, you will not have to worry about anything since the installer would be in charge of the logistics.

Aspects to keep in mind when choosing this option.

1. You still have to pay the freight fee to the installer (or dock hold for the installer to pick up the lift)

2. We will quote th e installation fee before you pay for the lift so that you can get an idea of the total amount to pay (car lift + freight + installation).

Do you have another delivery option in mind? In that case, do not hesitate to contact us. At Mechanic Superstore, we are open to all kinds of solutions, as long as they comply with the relevant local regulations and safety standards.

Katool KT-AV651 Wheel Alignment Machine

The Katool KT-AV651 Wheel Alignment Machine is a high-performance, mobile 3D aligner designed to work with both 2 post lifts and scissor lifts, giving your shop flexibility in deployment. It is built for everyday use in busy service bays and offers a powerful combination of features that aim to simplify alignment work for modern vehicles. With a power input range from 100 V to 240 V (single phase), it adapts to diverse workshop electrical environments while handling operating temperatures from 41 °F to 104 °F. The KT-AV651 can align tire diameters from 9 27/32 inches up to 31 1/2 inches, allowing it to service many passenger car and light truck wheels without needing a separate unit.

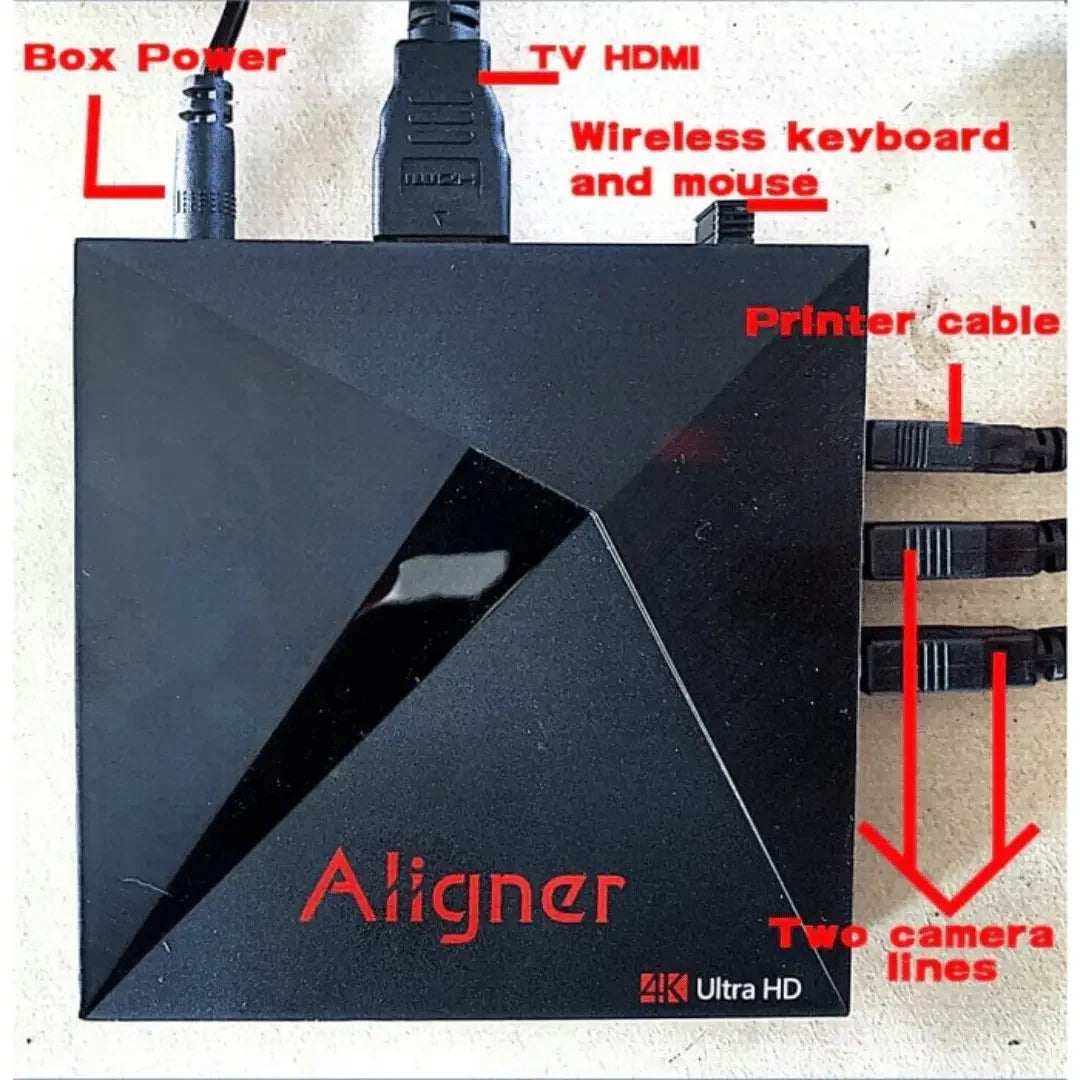

One of the strengths of this wheel alignment machine is its large free memory bank for vehicle specifications and a calibration-free installation process, meaning setup time is minimized and shops can begin alignment work almost immediately. The system includes a tablet and 30-inch display, plus mouse, keypad, and a printer to complete the diagnostic workflow. For connectivity, a WiFi device and USB drive are provided, allowing seamless data transfer. The software is compatible with Android and iOS, reducing dependency on proprietary platforms and making updates or upgrades easier to manage.

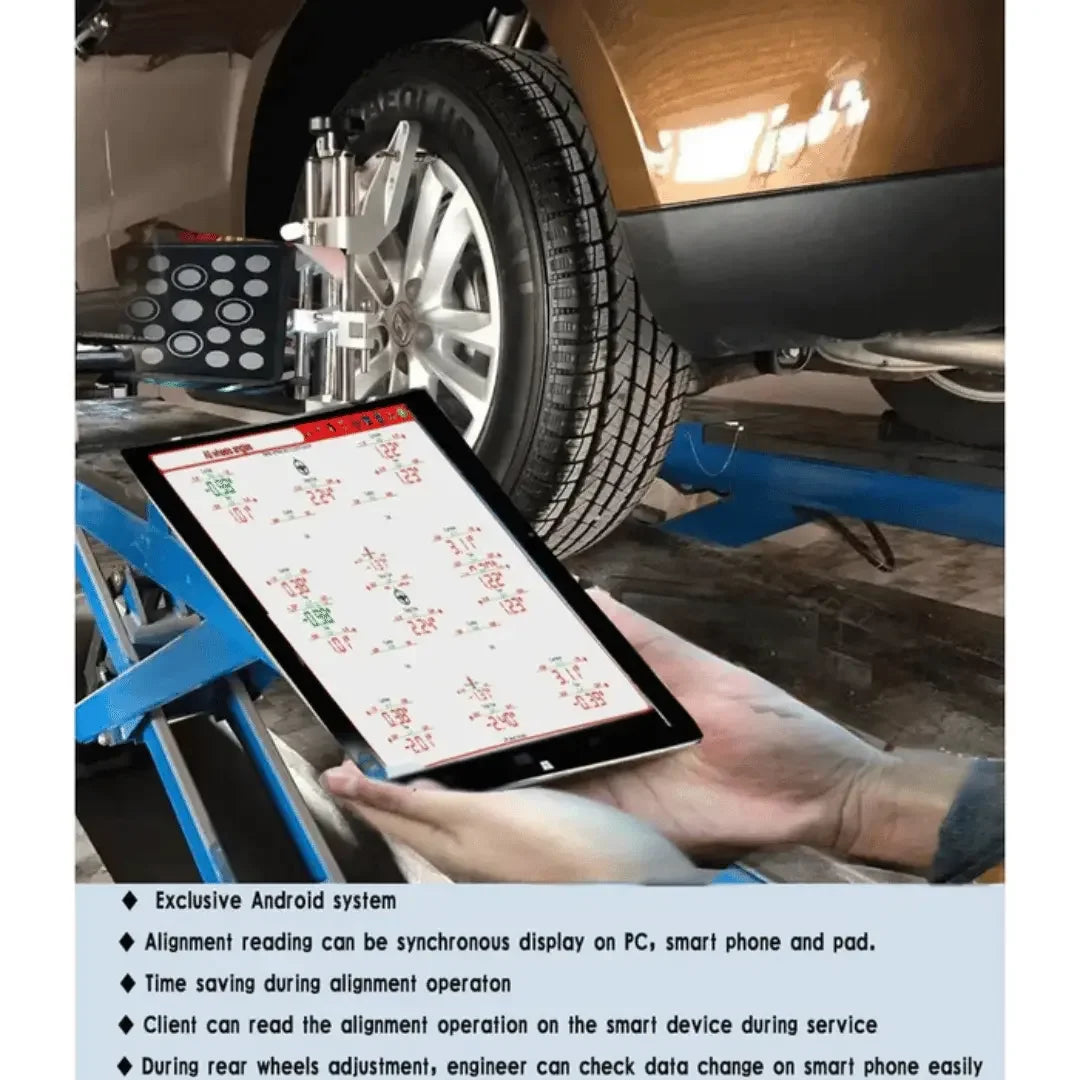

During alignment, sync display features let clients or technicians view real-time alignment parameters via their smartphones or tablets, enhancing transparency and communication. Manual post movement provides operational flexibility to accommodate different lift placements or shop layouts. The database updates yearly at no additional cost, keeping the machine current with the newest vehicle models across American, European, and Asian brands.

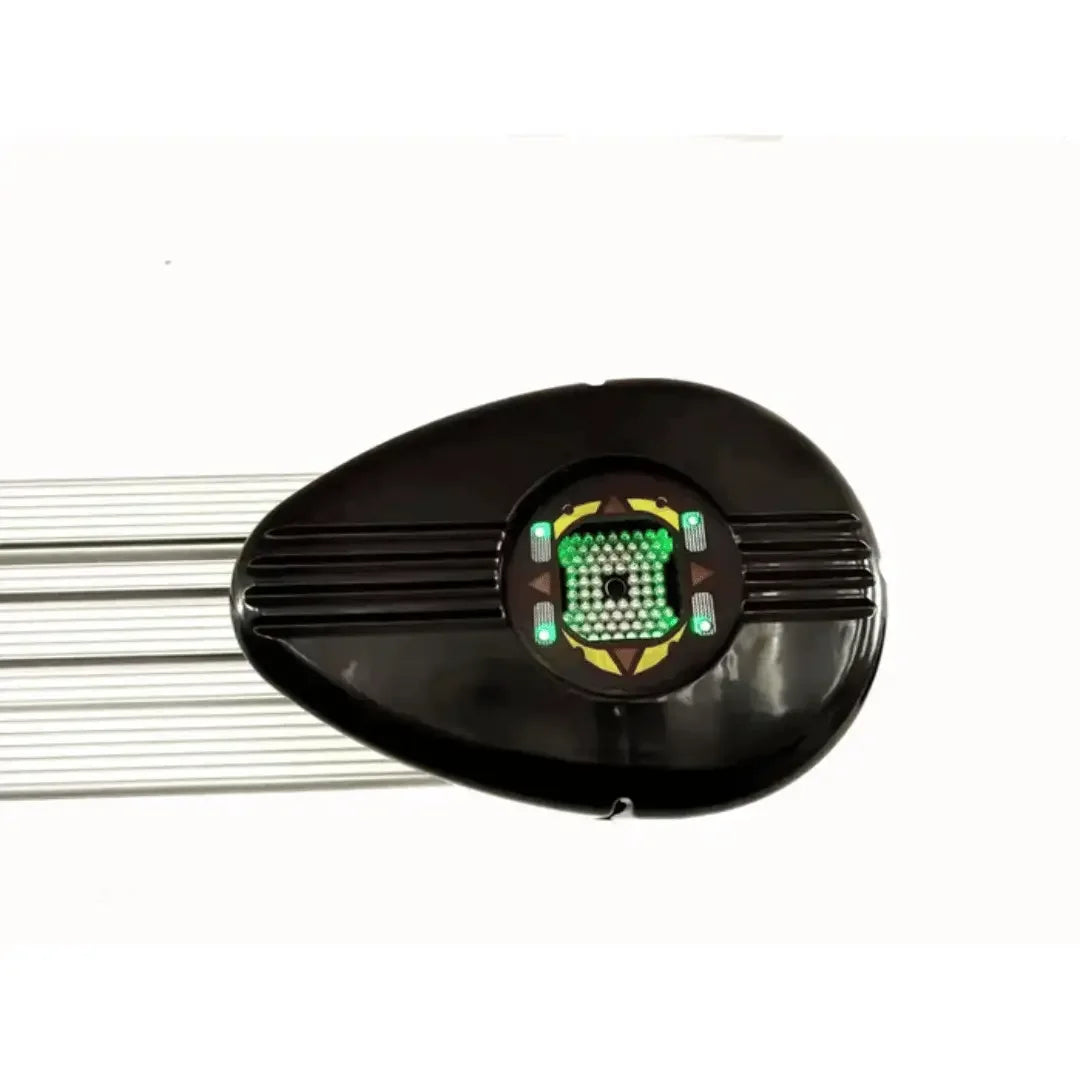

Technically, the KT-AV651 uses a dual-camera setup for its 3D alignment measurements. Wheelbase range supported is from 62 63/64 inches to 82 43/64 inches, and it supports track widths from 70 55/64 up to 177 11/64 inches. The unit weighs around 440.92 lbs, making it substantial but still mobile. The robust design ensures the system remains stable during use to maintain alignment accuracy. The KT-AV651 is offered with a one-year limited parts warranty.

When you incorporate this machine into your shop, you gain a versatile alignment solution that can adapt to both 2 post and scissor lifts. That flexibility reduces the need for multiple alignment systems and lets you optimize bay usage. The combination of broad vehicle coverage, calibration-free operation, and remote display features help boost productivity and reduce errors.

Contact us for more information.

Product Features

- Mobile 3D Wheel Aligner for Lift Application

- Unlimited memory for vehicle specifications

- No calibration during installation

- Includes tablet and a 30inch display screen, mouse and keypad, and a printer

- Complementary wifi device and USB drive

- Uses Android and IOS systems for the software, minimizes the need for software and system maintenance

- Synchronous Display on Smart Phone and Pad

- The client can read the alignment operation on the smart device during the service

- During rear wheel adjustment, the engineer can check data changes on a smartphone easily

- The post moves manually

- Free database upgrades yearly

- The database keeps up with the most recent car models from all US, European and Asian brands.

Product Specifications

|

Power Supply |

100-240V,50/60 HZ,1 Ph |

|

Working Temperature |

41F104 F(+5?+40?) |

|

Cameras (Total) |

2 |

|

Tire Diameter |

9 27/32-31 1/2 in(250-800 mm) |

|

Wheellbase |

62 63/64 -82 43/64 in(1.6-2.1m) |

|

Track Width |

70 55/64-177 11/64 in(1.8 -4.5 m) |

|

Warranty |

1-Year Limited |

|

Product Weight |

440.92 Ibs(200 kg) |

|

Shipping Weight |

529.11 Ibs(240 kg) |

|

Shipping Dimensions |

29.92x48.03x47.24 in(760x1220x1200mm) 110.24x12.6x15.75 in(2800x320x400mm) |

Wheel Alignment Machine Installation – Quick Guide

- Prepare Site: Use a level surface with clear space for vehicle approach and lift.

- Unpack & Inspect: Check for all parts, damage, and review the manual.

- Set Up Lift/Targets: Install turn plates/slip plates; align with machine specs.

- Mount Sensors/Cameras: Secure towers or cameras at correct height and distance.

- Connect Power: Plug into correct voltage and properly ground.

- Calibrate System: Follow manufacturer steps for sensor and camera calibration.

- Software Setup: Install/update software, input shop info, and test system.

Pick Up and Delivery

Call, text, or chat with us if you have questions 866-774-7743