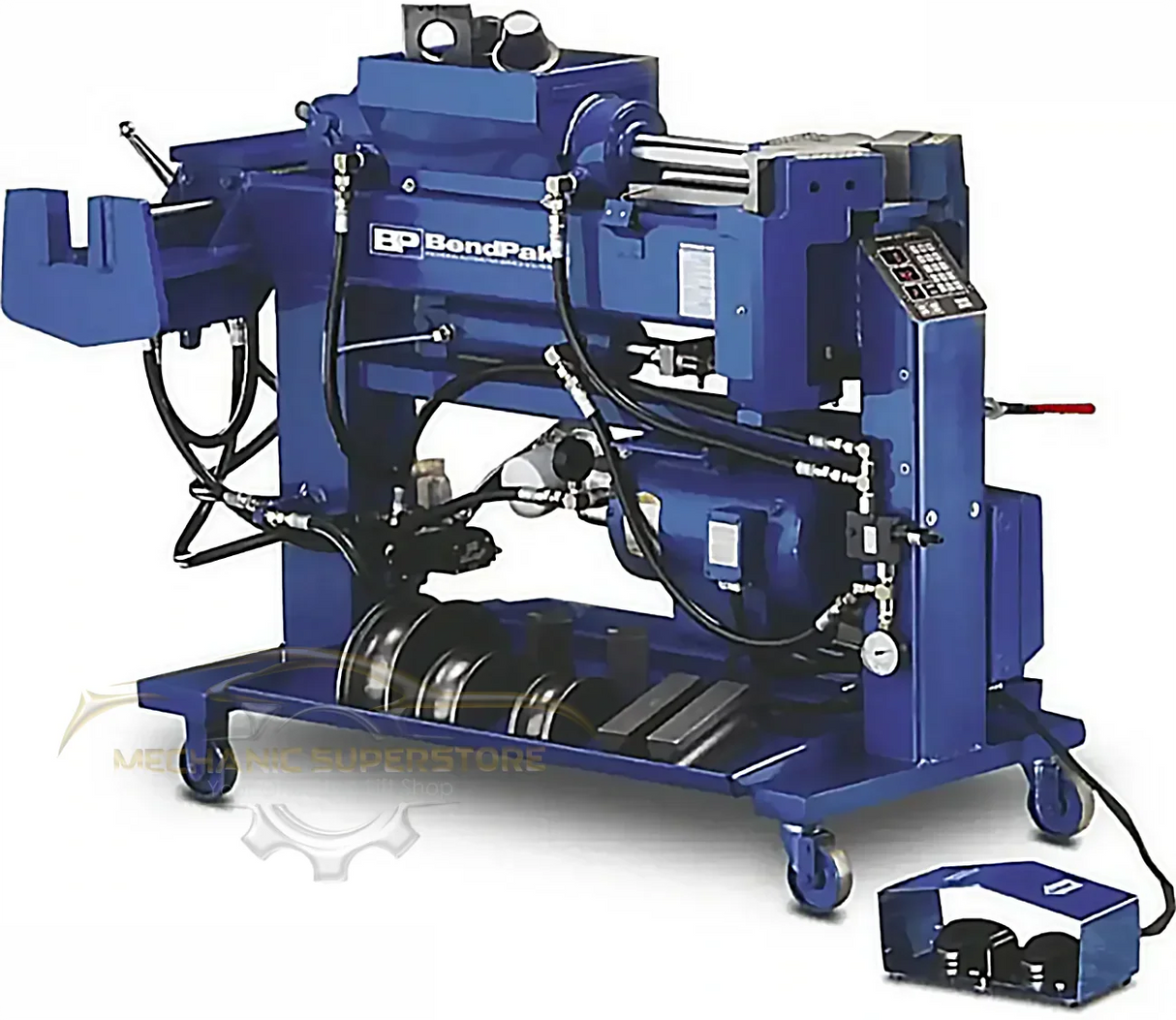

BendPak Digital Automatic Pipe Bender W/Metric Tooling Package

Use this calculator to estimate your shipping and pickup options.

Calculate Shipping

Shipping-FAQ's

Shipping Info

At Mechanic Superstore, our commitment is to provide you with the best customer service possible. For this reason, we offer you all kinds of delivery options so that you can choose the one that suits you best.

I Have The Equipment To Unload My Order

- Do you have a forklift, a high-capacity hoist, or a tractor in your facility? In that case, this option may be the one for you.Aspects to keep in mind when choosing this option.

- The most popular 2-post lifts (with 9,000 lb and 10,000 lb capacity) have a shipping weight of approximately 1,400 lbs and 1,900 lbs, respectively. On the other hand, a 15,000 lb capacity 2-post lift has a 2,700 lb shipping weight.

- Given the packaged lift and hydraulic power unit’s weight, they cannot be unloaded from the trailer by hand. Simply put, IT IS MANDATORY TO USE A SUITABLE FORKLIFT OR HOIST FOR UNLOADING THE LIFT.

- You are solely responsible for unloading your equipment from the truck. The truck driver cannot do this for you.

- Mechanic Superstore uses trustworthy freight companies to make the deliveries. It is your responsibility to be present on the scheduled date and time of the delivery.

- There will be a receiver charge of $135 if the truck driver arrives at the designated location and the customer does not have the necessary means ready to unload the lift.

- In case you do not have the necessary equipment to unload the equipment do not worry. Mechanics Superstore offers other delivery options.

Do you have a hitch trailer to transport your lift? If so, then this might be the best option.

Aspects to keep in mind when choosing this option.

1. Mechanics Superstore and our brands’ warehouses have the means to load your car lift into an appropriate trailer.

2. Given the weight and dimensions of car lifts, we cannot load lifts directly into vehicles or trucks. To safely transport your lift, you will need a hitch trailer. Will this option not work for you? Perhaps the warehouse is too far from your location? If so, keep reading.

Think of this option as a variation of the previous one. Even so, this could be an excellent alternative to picking up the lift at one of our warehouses. Instead, we can take the car lift to a warehouse closer to your location.

You will still need a hitch trailer to transport the lift for this option, but you can save on freight costs if you have an LTL Carrier close to your shop.

Neither of the above delivery options suits you? Then we have the solution.

We will dispatch your lifts directly to a local installer in your area. This way, you will not have to worry about anything since the installer would be in charge of the logistics.

Aspects to keep in mind when choosing this option.

1. You still have to pay the freight fee to the installer (or dock hold for the installer to pick up the lift)

2. We will quote th e installation fee before you pay for the lift so that you can get an idea of the total amount to pay (car lift + freight + installation).

Do you have another delivery option in mind? In that case, do not hesitate to contact us. At Mechanic Superstore, we are open to all kinds of solutions, as long as they comply with the relevant local regulations and safety standards.

BendPak Digital Automatic Pipe Bender With Metric Tooling Package - 208-460V / 50Hz / 3 Phase

The BendPak digital automatic pipe bender with metric tooling package is a high-precision machine designed for demanding exhaust, fabrication, and pipe bending workloads in professional shops. This machine provides digital, programmable bending control, allowing operators to input exact bending angles and store repeatable settings, which helps eliminate guesswork and saves time when repeating similar bends.

The pipe bender is capable of both automatic and manual modes, giving fabricators flexibility when handling a mixture of complex and simple bending tasks. With the metric tooling package included, this bender comes with a set of metric dies such as 38 mm, 42 mm, 45 mm, 48 mm, 51 mm, and 60 mm sizes, enabling work with common metric tubing without needing conversion tooling. The metric tooling is especially beneficial in regions and for OEM fabrications where metric pipe sizes are standard, and it ensures that the machine adapts to a wide variety of fabrication workflows.

Digital controls are housed in the upright post of the pipe bender, with a keypad interface that supports memory of up to 99 programmable bend depths. The operator can quickly select common bend angles, set custom values, and monitor live die angle readings during the bending process. This programmable capability is especially useful for shops performing repeated or mirrored bends, reducing setup time between jobs. The control module is fully enclosed to protect it from swarf, fluids, and shop environment interference, helping to maintain consistent performance and longevity under shop conditions.

For usability, the pipe bender includes industrial casters to assist with positioning before anchoring. The bend dies and swaging tools are quick-release and twist-lock, allowing fast changeovers during job transitions. The tooling tray and organization features simplify setup and reduce downtime. A drop-in collar simplifies swaging operations, allowing rapid transitions between bending and expanding steps. The machine also supports remote foot control so operators can trigger bending while standing near the workpiece. All of these features combine to optimize workflow and reduce handling.

Contact us for more pipe bender or garage equipment information.

Product Features

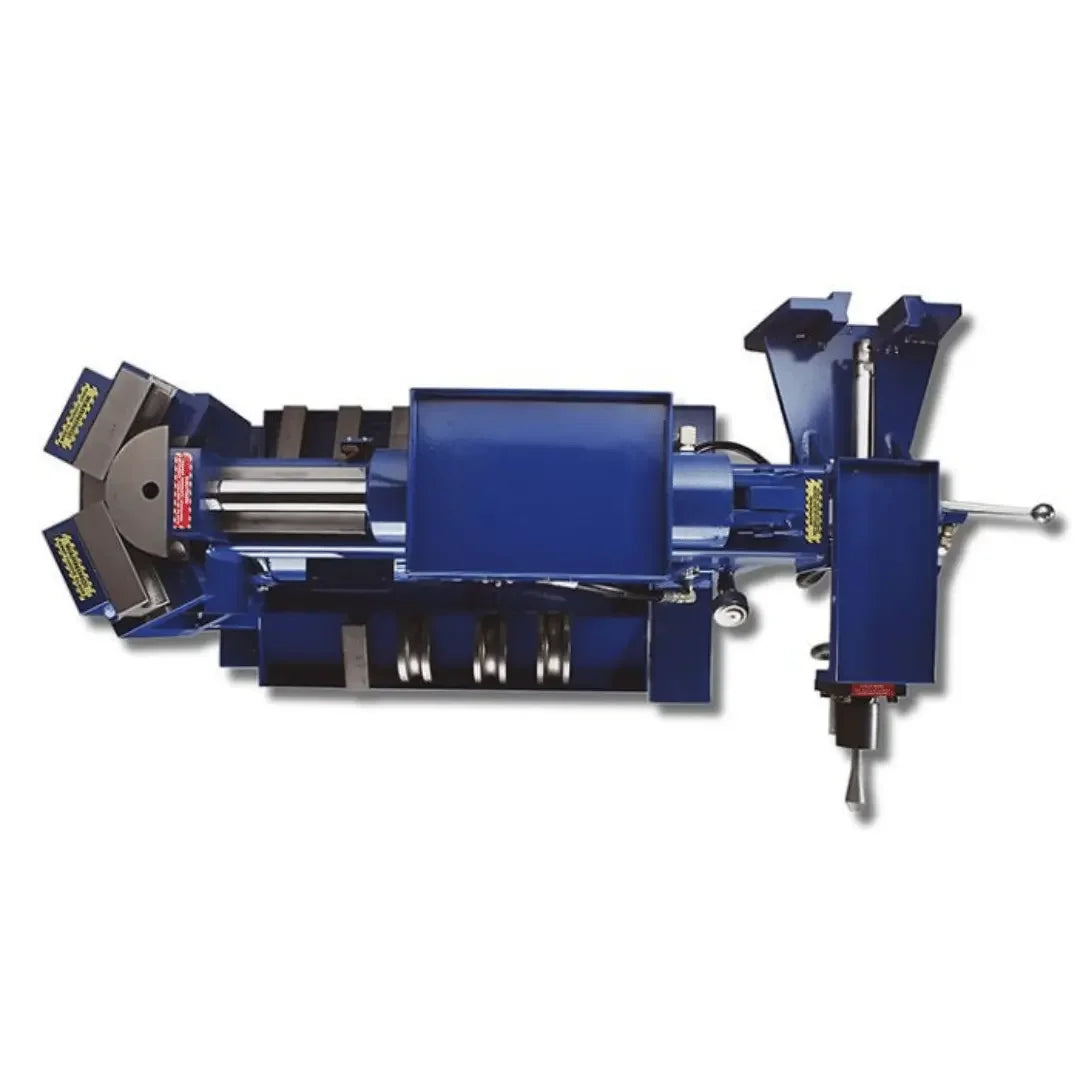

- 2 separate end-finishing units at rear for all necessary flaring and expanding

- Comes complete with quick release bending and finishing dies

- Includes high-speed clampless swager and internal expander

- Easy-to-use drop-in collar makes swaging operations quick and efficient

- Twist-lock tooling

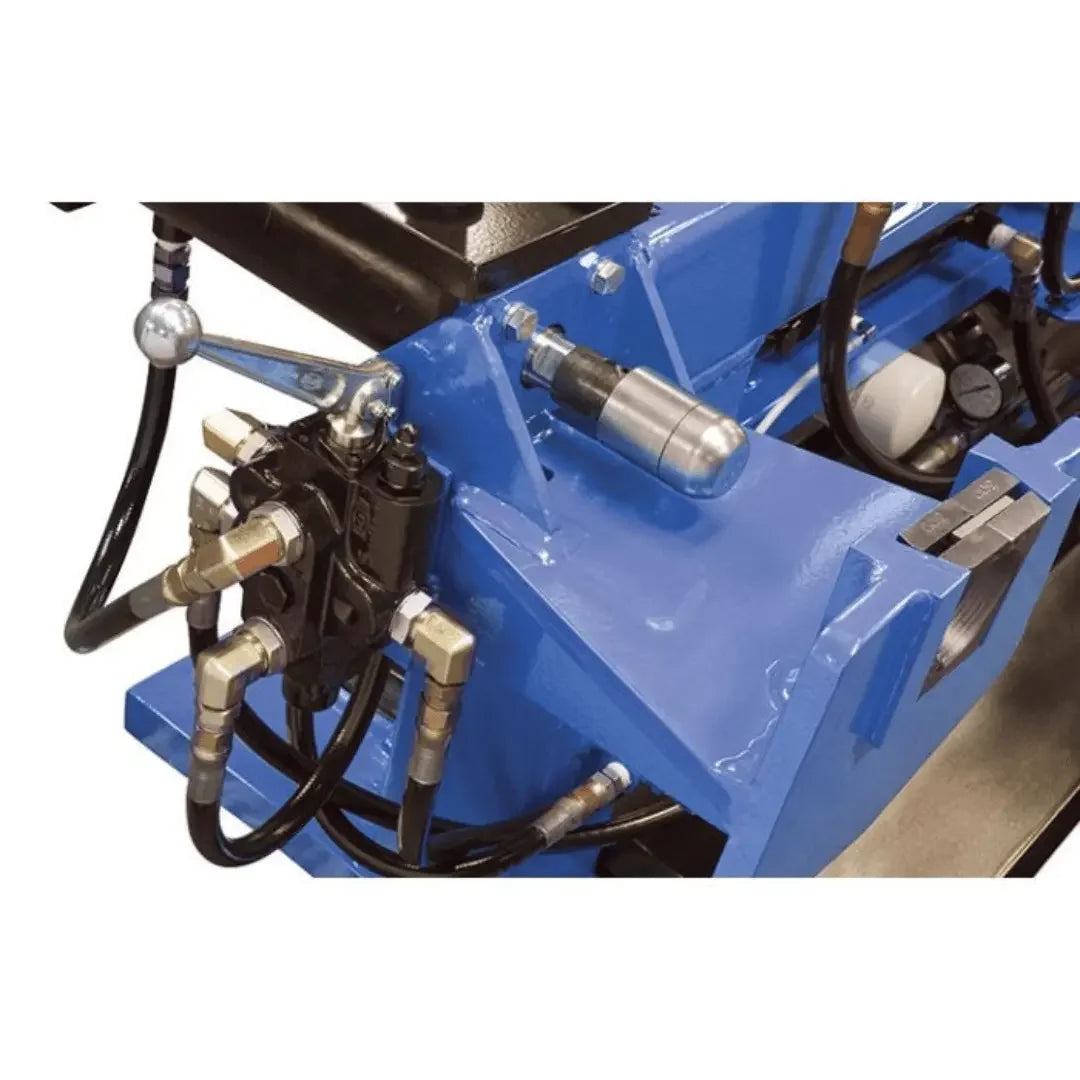

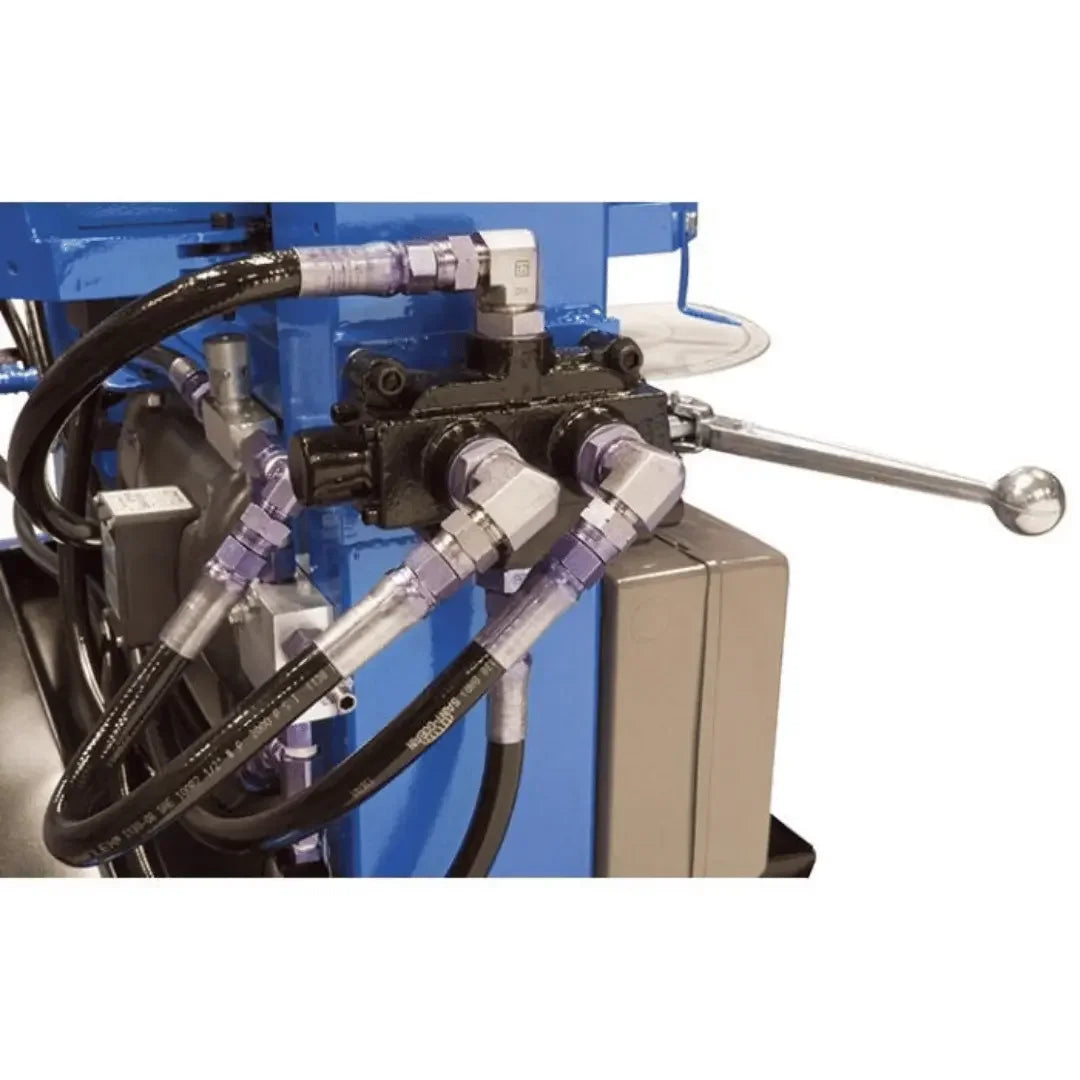

- Integrated power-relief control valve

- Pass-through cylinder stem passes completely through the primary frame

- Rigid 6" x 6" x 3/8" welded-steel tube frame

- Commercial-grade hydraulic cylinders

- Standard grease fittings allow for simple lubrication

- NEMA-rated on / off switch box incorporates overload relays that automatically disrupt power supply should an unforeseen over-current situation occur

- Pressure gauges let you know exactly what the system pressures are at all times

- Industrial grade casters help you easily move the bender around your shop

- Adjustable pressure valve located right up front

- One-piece barrel ensures that the bending gates stay perfectly aligned with the ram

- Heat-treated tooling for greater service life

- Convenient tool trays keep your tooling organized

- Strong, 5 HP energy efficient motor delivers maximum performance

- Direct-drive, high-speed, 4 gpm pump

- Single enclosed bottom cylinder applies pressure evenly to the back gates and, because it is hidden, does not interfere with the tubing

- Large capacity fluid reservoir keeps the hydraulic oil running cooler and prevents contamination

- Canister oil filter in the hydraulic system keeps the oil nice and clean

- Oil sight-gauges allow you to visually inspect oil levels

- Over-sized 1/2" high-pressure hose provides better speed and cooling

- Open-sided swager box allows for easier access and reduces the chance of "crashing" tools and damaging the cylinder

- 180° bending die available

Product Specifications

Overview

| Bending Controls | Automatic / Digital |

| Expander Controls | Manual |

| Frame Style | Double-Ended Expander |

| Max. Tube Capacity | 3" (76 mm) .095 wall |

Bending

| Max. Bending Radius | 5" (127 mm) |

| Min. Bending Radius | 3.3" (89 mm) |

Hydraulics

| Top Cylinder Force | 60,000 lbs. (27,216 kg) |

| Hydraulic Filter | Canister |

| Motor | 5 HP / 208-460 VAC / 50 Hz / 3 PH |

Die Pack

| Standard | 1.5", 1.75", 1.625", 2", 2.25", 2.5" (302) |

Dimensions

| Width | 41" (1,041 mm) |

| Depth | 64" (1,626 mm) |

| Depth | 26" (660 mm) |

Shipping

| Weight | 1,388 lbs. |

| Dimensions | 48" x 70" x 30" (1,219 mm x 1,778 mm x 762 mm) |

Pick Up and Delivery

Our Pick Up locations for BendPak are located in Santa Paula, California & Theodore, Alabama.

Call, text, or chat with us if you have questions. 866-774-7743