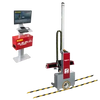

Corghi Remo Compact Clampless Wheel Alignment System

Couldn't load pickup availability

Shipping-FAQ's

Shipping Info

At Mechanic Superstore, our commitment is to provide you with the best customer service possible. For this reason, we offer you all kinds of delivery options so that you can choose the one that suits you best.

I Have The Equipment To Unload My Order

- Do you have a forklift, a high-capacity hoist, or a tractor in your facility? In that case, this option may be the one for you.Aspects to keep in mind when choosing this option.

- The most popular 2-post lifts (with 9,000 lb and 10,000 lb capacity) have a shipping weight of approximately 1,400 lbs and 1,900 lbs, respectively. On the other hand, a 15,000 lb capacity 2-post lift has a 2,700 lb shipping weight.

- Given the packaged lift and hydraulic power unit’s weight, they cannot be unloaded from the trailer by hand. Simply put, IT IS MANDATORY TO USE A SUITABLE FORKLIFT OR HOIST FOR UNLOADING THE LIFT.

- You are solely responsible for unloading your equipment from the truck. The truck driver cannot do this for you.

- Mechanic Superstore uses trustworthy freight companies to make the deliveries. It is your responsibility to be present on the scheduled date and time of the delivery.

- There will be a receiver charge of $135 if the truck driver arrives at the designated location and the customer does not have the necessary means ready to unload the lift.

- In case you do not have the necessary equipment to unload the equipment do not worry. Mechanics Superstore offers other delivery options.

Do you have a hitch trailer to transport your lift? If so, then this might be the best option.

Aspects to keep in mind when choosing this option.

1. Mechanics Superstore and our brands’ warehouses have the means to load your car lift into an appropriate trailer.

2. Given the weight and dimensions of car lifts, we cannot load lifts directly into vehicles or trucks. To safely transport your lift, you will need a hitch trailer. Will this option not work for you? Perhaps the warehouse is too far from your location? If so, keep reading.

Think of this option as a variation of the previous one. Even so, this could be an excellent alternative to picking up the lift at one of our warehouses. Instead, we can take the car lift to a warehouse closer to your location.

You will still need a hitch trailer to transport the lift for this option, but you can save on freight costs if you have an LTL Carrier close to your shop.

Neither of the above delivery options suits you? Then we have the solution.

We will dispatch your lifts directly to a local installer in your area. This way, you will not have to worry about anything since the installer would be in charge of the logistics.

Aspects to keep in mind when choosing this option.

1. You still have to pay the freight fee to the installer (or dock hold for the installer to pick up the lift)

2. We will quote th e installation fee before you pay for the lift so that you can get an idea of the total amount to pay (car lift + freight + installation).

Do you have another delivery option in mind? In that case, do not hesitate to contact us. At Mechanic Superstore, we are open to all kinds of solutions, as long as they comply with the relevant local regulations and safety standards.

Corghi Remo Compact Clampless Wheel Alignment System

The Corghi REMO Compact clampless wheel alignment system offers a next-generation approach to alignment checks by eliminating the need for rim contact or physical clamps. As vehicles drive into position, the system’s advanced optical sensors instantly capture alignment parameters without requiring any manual sensor attachments or wheel clamps. This touchless, drive-through method accelerates service flow, reduces handling errors, and prevents rim damage—especially significant when working with expensive alloy or custom wheels. The system is especially effective for high throughput shops, inspection lanes, or service bays where minimizing technician intervention and maximizing uptime are critical.

Under the hood, the REMO Compact system relies on high-resolution camera optics and precision imaging algorithms to measure toe, camber, castor, thrust angle, and steering angle differences. The system uses dynamic compensation to correct for wheel run-out, hub imperfections, or minor surface irregularities, maintaining alignment accuracy even when components are not perfectly seated. The real-time feedback loop displays current values while the technician adjusts, offering color-coded guidance that highlights deviations from specified ranges. This visual clarity helps reduce alignment cycle time and ensures consistent results across different operators.

Because the system is fully clampless and noncontact, alignment setup time virtually disappears. Technicians no longer must attach targets, clamps, or sensors to each wheel—tasks which can introduce vertical play or misalignment if not secured perfectly. Instead, the REMO Compact system scans automatically as the vehicle enters the alignment bay, completing a full alignment precheck in seconds. Only vehicles exhibiting out-of-spec readings require further corrective work, allowing shops to triage alignment needs rapidly and maintain high throughput.

The REMO Compact system maintains a comprehensive internal vehicle database containing alignment specification limits for many makes and models. This database supports model selection, spec recall, and guided adjustment procedures. Technicians can reliably access factory tolerances at the workstation, reducing lookup errors or guesswork. Over time, software updates expand this database to include new vehicles, ensuring the system stays current. The interface is designed to be intuitive, with prompts, menus, and live indicator bars that guide users during measurement and adjustment workflows.

Sensor calibration and management are simplified by the system’s design. Optical sensor heads are engineered for rugged shop environments, resistant to dust, vibration, and moderate impact. The system periodically self-checks and advises when calibration is needed. Because the design is contact-free, there is no wear on clamp surfaces or mechanical sensor parts, which reduces long-term maintenance costs. Sensor mounting and charging stations are built for easy access, making service checks and part replacement efficient and straightforward.

Flexibility is a hallmark of the REMO Compact system. It can support wired or wireless sensor configurations, giving shops the choice to minimize cable clutter or ensure reliable data in environments with radio interference. Wireless operation facilitates sensor repositioning and layout changes without rewiring. The system automatically synchronizes sensors and maintains communication integrity across the 2.4 GHz link while continuously streaming alignment data during scans.

In terms of workflow, using the REMO Compact system transforms alignment lanes into high-efficiency inspection stations. As customers drive in, alignment scans occur transparently, delivering instant feedback on whether a full alignment adjustment is necessary. Vehicles that pass checks can be cleared quickly, while only those requiring correction occupy technician time. This precheck filtering frees up workshop capacity and reduces labor spent on unnecessary procedures. The technology also improves transparency when communicating with customers, because results can be displayed or printed immediately, showing before/after values in clear, visual format.

The Corghi REMO Compact clampless wheel alignment system is engineered for long life. Its optical elements are sealed and protected against contaminants, its enclosures resist mechanical damage, and its software architecture ensures stable, repeatable performance.

Contact us for more wheel alignment system information.