Shipping-FAQ's

Shipping Info

At Mechanic Superstore, our commitment is to provide you with the best customer service possible. For this reason, we offer you all kinds of delivery options so that you can choose the one that suits you best.

I Have The Equipment To Unload My Order

- Do you have a forklift, a high-capacity hoist, or a tractor in your facility? In that case, this option may be the one for you.Aspects to keep in mind when choosing this option.

- The most popular 2-post lifts (with 9,000 lb and 10,000 lb capacity) have a shipping weight of approximately 1,400 lbs and 1,900 lbs, respectively. On the other hand, a 15,000 lb capacity 2-post lift has a 2,700 lb shipping weight.

- Given the packaged lift and hydraulic power unit’s weight, they cannot be unloaded from the trailer by hand. Simply put, IT IS MANDATORY TO USE A SUITABLE FORKLIFT OR HOIST FOR UNLOADING THE LIFT.

- You are solely responsible for unloading your equipment from the truck. The truck driver cannot do this for you.

- Mechanic Superstore uses trustworthy freight companies to make the deliveries. It is your responsibility to be present on the scheduled date and time of the delivery.

- There will be a receiver charge of $135 if the truck driver arrives at the designated location and the customer does not have the necessary means ready to unload the lift.

- In case you do not have the necessary equipment to unload the equipment do not worry. Mechanics Superstore offers other delivery options.

Do you have a hitch trailer to transport your lift? If so, then this might be the best option.

Aspects to keep in mind when choosing this option.

1. Mechanics Superstore and our brands’ warehouses have the means to load your car lift into an appropriate trailer.

2. Given the weight and dimensions of car lifts, we cannot load lifts directly into vehicles or trucks. To safely transport your lift, you will need a hitch trailer. Will this option not work for you? Perhaps the warehouse is too far from your location? If so, keep reading.

Think of this option as a variation of the previous one. Even so, this could be an excellent alternative to picking up the lift at one of our warehouses. Instead, we can take the car lift to a warehouse closer to your location.

You will still need a hitch trailer to transport the lift for this option, but you can save on freight costs if you have an LTL Carrier close to your shop.

Neither of the above delivery options suits you? Then we have the solution.

We will dispatch your lifts directly to a local installer in your area. This way, you will not have to worry about anything since the installer would be in charge of the logistics.

Aspects to keep in mind when choosing this option.

1. You still have to pay the freight fee to the installer (or dock hold for the installer to pick up the lift)

2. We will quote th e installation fee before you pay for the lift so that you can get an idea of the total amount to pay (car lift + freight + installation).

Do you have another delivery option in mind? In that case, do not hesitate to contact us. At Mechanic Superstore, we are open to all kinds of solutions, as long as they comply with the relevant local regulations and safety standards.

CORGHI EXACT LINEAR WHEEL ALIGNMENT SYSTEM

The Corghi Exact Linear Plus 3D Wheel Alignment System is built for workshops that want state-of-the-art alignment performance with maximum flexibility and ease of use. With its camera-based alignment technology, this system brings precision, speed, and expandability to modern vehicle servicing. From the moment a vehicle arrives, the alignment process is made smoother by features such as clampless sensor operation, intelligent software support, and the ability to handle even advanced driver assistance systems calibrations.

At its core, the Exact Linear Plus 3D system uses a pair of high resolution “HI-Q” cameras in a 3D format to capture alignment data from all four wheels quickly and accurately. This dual camera design enables live angle tracking and compensates for run-out dynamically, eliminating errors caused by hub or wheel irregularities. The system reads values such as camber, caster, toe, thrust angle, and cumulative alignment metrics, offering the technician real-time feedback while adjustments are made. Its intuitive interface helps guide the operator step by step, ensuring that even complex adjustments can be completed confidently.

One standout characteristic of the system is its wireless capability. Using 2.4 GHz industrial radio technology, the sensors can communicate wirelessly with the main processing unit, reducing cable clutter and improving efficiency in tight workshop environments. Despite the wireless capability, the system retains support for wired connections for added reliability in challenging signal environments. This hybrid approach ensures that no matter the layout or shop constraints, the Exact Linear Plus 3D remains functional and dependable.

The software architecture is based on a refined version of Corghi’s Exact Plus platform, delivering both visual clarity and operational control. It runs on a Windows Embedded base and features selectable tutorials, real-time graphical indicators, and a built-in vehicle specification database covering tens of thousands of different models. The technician can recall custom settings, store alignment results by customer or vehicle, and generate printouts with ease. The display shows live adjustment values, warns when out of spec limits, and directs rechecks where needed, helping to reduce rework and improve throughput.

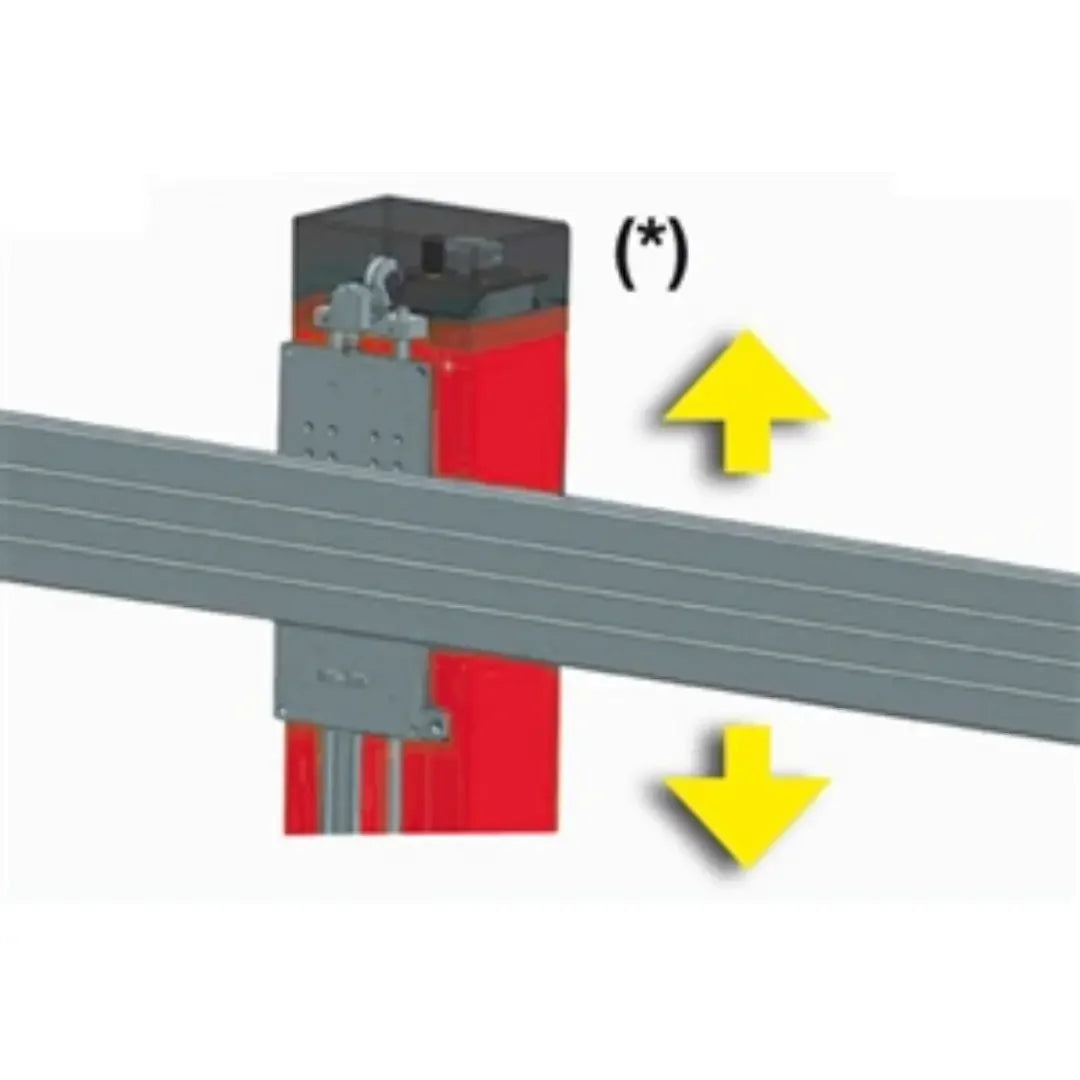

Physically, the wheel alignment system is engineered to integrate seamlessly with lifts or pits. The camera housing and sensor heads are robust enough to endure typical shop conditions.

The Exact Linear Plus 3D system supports touchless and clampless pre-check alignments, meaning no wheel clamps or contact with rims are required during initial scanning. This reduces risk of scratching or damaging wheels, and speeds the pre-alignment process. Every measurement is processed with differential image techniques to compensate for ambient reflections, lighting changes, and slight movements, increasing reliability even in difficult lighting conditions.

Beyond traditional alignment tasks, the system is ready for future calibration needs linked to advanced driver assistance systems (ADAS). It is compatible with Corghi’s PROADAS universal calibration tools, enabling the same platform to support camera, radar, and lidar calibration tasks as required by many modern vehicles. This future-proof capability extends the system’s usefulness as vehicle technology evolves.

Maintenance and calibration are made simple. The system ships factory calibrated, and after installation only periodic checks and calibration are required. The optical and mechanical parts are easily accessible for cleaning, and the software includes routines to guide the technician through calibration sequences. Firmware updates and specification database expansions can be applied when needed, ensuring the system stays current with evolving vehicle models and standards.

The Corghi Exact Linear Plus 3D Wheel Alignment System offers a compelling balance of performance, automation, and expandability for alignment shops that want to stay ahead in a rapidly changing automotive landscape. Its combination of wireless intelligence, precise optics, guided software, and ADAS readiness makes it a professional choice for accurate, high throughput alignment operations.

Contact us for more information on purchasing your next wheel alignment system.